Journey of a French Fry: How Lineage Keeps French Fries Fresh from Field to Fry Basket

April 10, 2025

Behind every plate of french fries is a complex, supply chain odyssey that begins long before you’ve taken your first bite. Every step of this journey, from the fertile fields of the Pacific Northwest to the fry basket at your favorite restaurant, relies on the precision and efficiency of a seamless cold chain. Lineage is an important driver in the food supply chain, helping ensure the freshness, flavor and quality of each french fry.

But what does that journey look like and how does Lineage help pave the way for that french fry to reach your plate? This is the story of how a simple potato is transformed into one of the world’s most beloved foods – and how Lineage’s logistics and cold chain expertise help keep the journey fresh at every stop.

Lineage's Journey of a French Fry

French fries have quite the cold chain journey. From field to fry basket, find out how Lineage gets french fries to a plate near you.

Cultivating the Perfect Potato

Cultivating the Perfect Potato

This journey begins in the United States’ Pacific Northwest. Washington and Idaho are famous for their ability to grow top-tier potatoes in the region’s Columbia Basin, where Lineage has 9 warehouses within a 100-mile radius. The magic of this region is in the soil. Fields in Washington and Idaho are made up of well-drained, fertile, volcanic soil, providing these tasty tubers the perfect environment to grow. When paired with the cool climate and ample sunshine of the region, you get a mecca for potato producers in the US. That’s why, as recently as 2023, 10.4 billion pounds of potatoes were grown in Washington and 14.3 billion pounds were grown in Idaho according to the USDA.

Once the potatoes are harvested, the race against time begins. Potatoes must be properly stored in humidity-controlled cellars to maintain their quality. This helps slow down the aging process to prevent spoilage before being processed.

Processing Potatoes into French Fries

After being properly stored, the transformation from potato to french fry begins with processing before reaching a Lineage warehouse. The first step of processing a potato into a french fry is cleaning. Each potato is cleaned to remove any dirt or debris. Next, they are peeled and cut into the familiar fry-shapes, from crinkle-cut and shoestring, to the classic shapes found at your favorite fast-food restaurants. From here, they are blanched to preserve their color, and lightly pre-fried to achieve the ideal texture. Before reaching the next phase of their journey, the french fries are packaged, palletized and prepared for shipment to one of Lineage’s nearby facilities.

The U.S. produces approximately 46.8 billion pounds of potatoes every year, with a significant portion destined for french fry production.

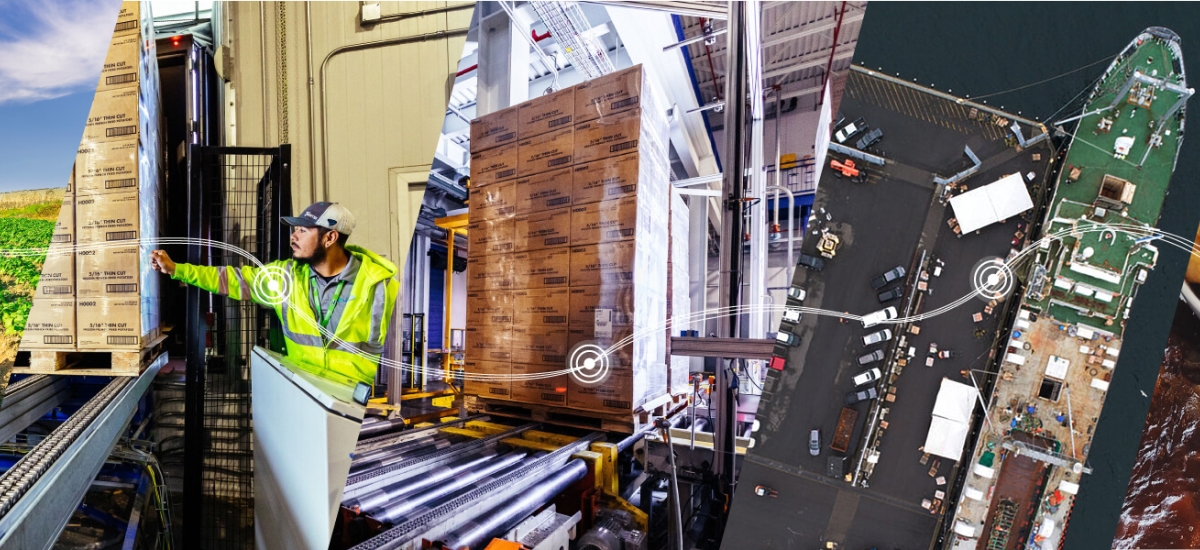

Locking In French Fry Freshness with Cold Storage Technology

Once they have been properly processed, it’s time to lock in that freshness at one of Lineage’s automated facilities in the region. Here, the pallets of fries are quickly sorted and put away, thanks to Lineage Eye, our patented automated receiving system. Fries are kept at the ideal temperature in our cold storage warehouse, preserving them for the next leg of their journey. The temperature-controlled environment of Lineage’s cold storage warehouse helps maintain the overall food quality of the french fries, while also locking in that familiar flavor. It also helps retain their crispiness when they’re cooked.

From here, the correct pallet of fries is selected from the warehouse inventory and prepped for shipment. Lineage uses warehouse automation to quickly and efficiently load the frozen fries onto temperature-controlled trucks. The speed and efficiency at the loading dock is essential to help ensure the fries remain at optimal cold chain conditions throughout the remainder of their journey.

Lineage manages an average potato inventory of approximately 240 million pounds in the U.S.!

Global and Domestic Distribution: Fries on the Fly

Global and Domestic Distribution: Fries on the Fly

Once loaded onto temperature-controlled trucks, the fries embark on one of two paths to the end of their journey:

Global Exporting

For international shipments, french fries must first be prepped for travel. Lineage’s freight forwarding and customs brokerage teams work behind the scenes to streamline the export process. They prepare export clearance documentation, secure space on the ocean vessel and schedule drayage for the fries to be transported to the Port of Tacoma. With these admin tasks taken care of, the fries are loaded onto container ships once they arrive in Tacoma, bound for countries like Japan. Because of Lineage’s export services, like freight forwarding and customs brokerage solutions, french fries smoothly navigate through international regulations and customs inspections at port locations. Upon international arrival, they’re stored in temperature-controlled, port-centric facilities to help maintain their quality before reaching restaurants and grocery stores.

Domestic Enjoyment

For domestic distribution, the fries are shipped from Lineage’s Washington-based facilities to foodservice distribution centers nationwide. From there, they are delivered to restaurants and grocery stores, helping ensure the quality of fries across the country.

Lineage’s annual inventory average of french fries in the U.S. is ~240M lbs.

Lineage Helps Guide Potatoes from Field to Fry Basket

Lineage Helps Guide Potatoes from Field to Fry Basket

From the fertile fields of the Columbia Basin to restaurant tables worldwide, the journey of a french fry is a remarkable blend of agriculture, technology and logistics. Lineage’s global integrated cold chain solutions help ensure each fry maintains its freshness, flavor and quality throughout this journey.

With a strategic network of cold storage warehouses, state-of-the-art technology and seamless international logistics, Lineage supports the french fry supply chain from start to finish. The next time you dip a fry into ketchup, remember the journey it took to get there.

Start Your Journey With Lineage

Learn more about the journey of a french fry, from field to fry basket, today!